Fleet management solutions have come a long way from basic vehicle tracking. Fleets today understand that reducing downtime is a multi-pronged approach that includes the often-overlooked component of driver education. Many fleet companies focus on maintenance schedules and parts availability, but the real difference-maker is who sits in front of the steering wheel.

According to Fleet Carma, vehicle downtime costs fleets over $3.3 billion each year. Mechanical problems alone cost fleets over $500 million. The greatest cost is in driver behaviour. These numbers show that truck management company approaches must include robust driver training programs.

How Driver Training Changes Fleet Performance

Driver training changes fleet performance by generating a more proactive maintenance culture. Drivers become mobile diagnosticians of their vehicle systems, warning lights, etc., to be able to identify issues before they become serious. This reduces the amount of heavy-duty roadside assistance and prevents needless breakdowns.

Financial Impact of Driver’s Education

While the immediate savings generated through driver education can be substantial, the savings that come from putting well-trained drivers on the road go well beyond just the immediate savings. Educated drivers help fleets to avoid the downstream costs of unexpected downtime, such as lost revenue (or service), unhappy customers, and the premium paid on emergency repairs. On average, 20% of a fleet’s vehicles encounter downtime due to accidents each year, with many preventable through training and awareness.

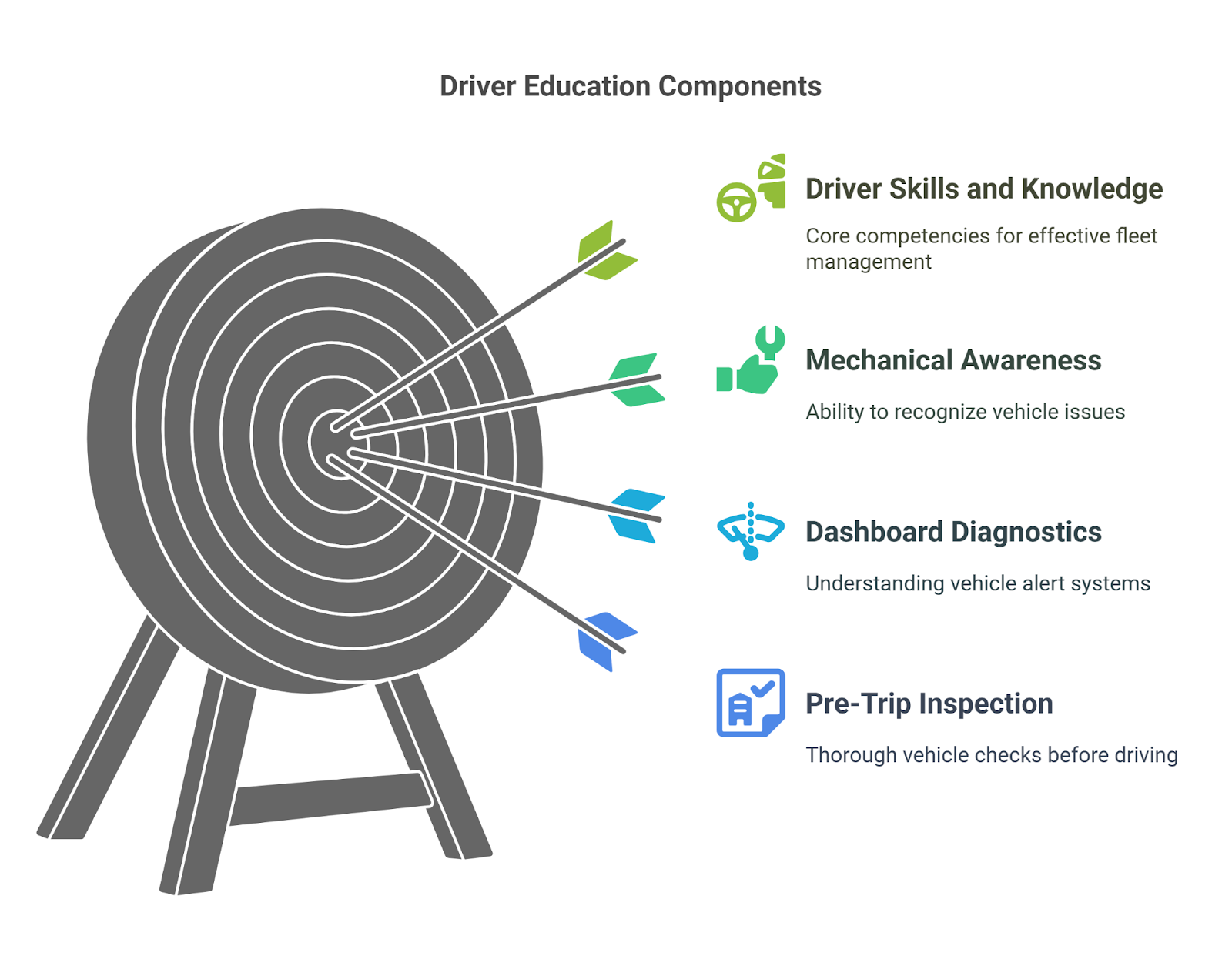

Essential Driver Education Components for Maximum Impact

The distinction between reactive and proactive fleet management has much to do with the driver’s skills and knowledge. Fleet driver training programs can have a powerful influence on fleet performance when many competencies are targeted. When drivers know what to look for and how to respond, they become drivers rather than simply operators protecting fleets.

Pre-Trip Inspection Standards

When drivers execute a complete pre-trip inspection, fleet maintenance and repair costs improve dramatically. Pre-trip inspections should be primarily about knowing what normal versus abnormal road conditions exist before driving.

For the pre-trip inspection, driver competencies include:

- Checking tire tread depth, pressure, and the correct weight for loading

- Job scope outline ensuring all braking systems have been visually checked and functioned

- Fluid level checks, information regarding the hydraulic connector, and knowing what liquid is leaking, if any exists. The most common fluid leakage is engine oil

- Checking electrical systems

- Coupling or hitching trailers

Dashboard Diagnostics

Raising the level of drivers’ understanding of dashboard diagnostics creates peace of mind so that they know how to react when alert lights or fault codes appear. Modern vehicles create copious diagnostic information, giving drivers awareness that they can connect reasonable interventions or quickly receive professional maintenance requirements if they stop working.

Drivers should know:

- The onboarding system has different acknowledgement displays that alert drivers to plan their next initiative

- Unrequired information or debugging situations will not be usable in daily vehicle operation

- Coordination and dispatch should err on the side of caution to verify lamp/fault codes have been noted or remain active if required to contact truck-side assistance

- Document the fault codes with clear supporting evidence for maintenance

Mechanical Awareness Training

Mechanical awareness training doesn’t aim to create mechanics but rather develops drivers’ ability to recognise abnormal sounds, vibrations, and performance changes. This awareness becomes crucial for preventing minor issues from becoming major failures requiring emergency roadside truck assistance.

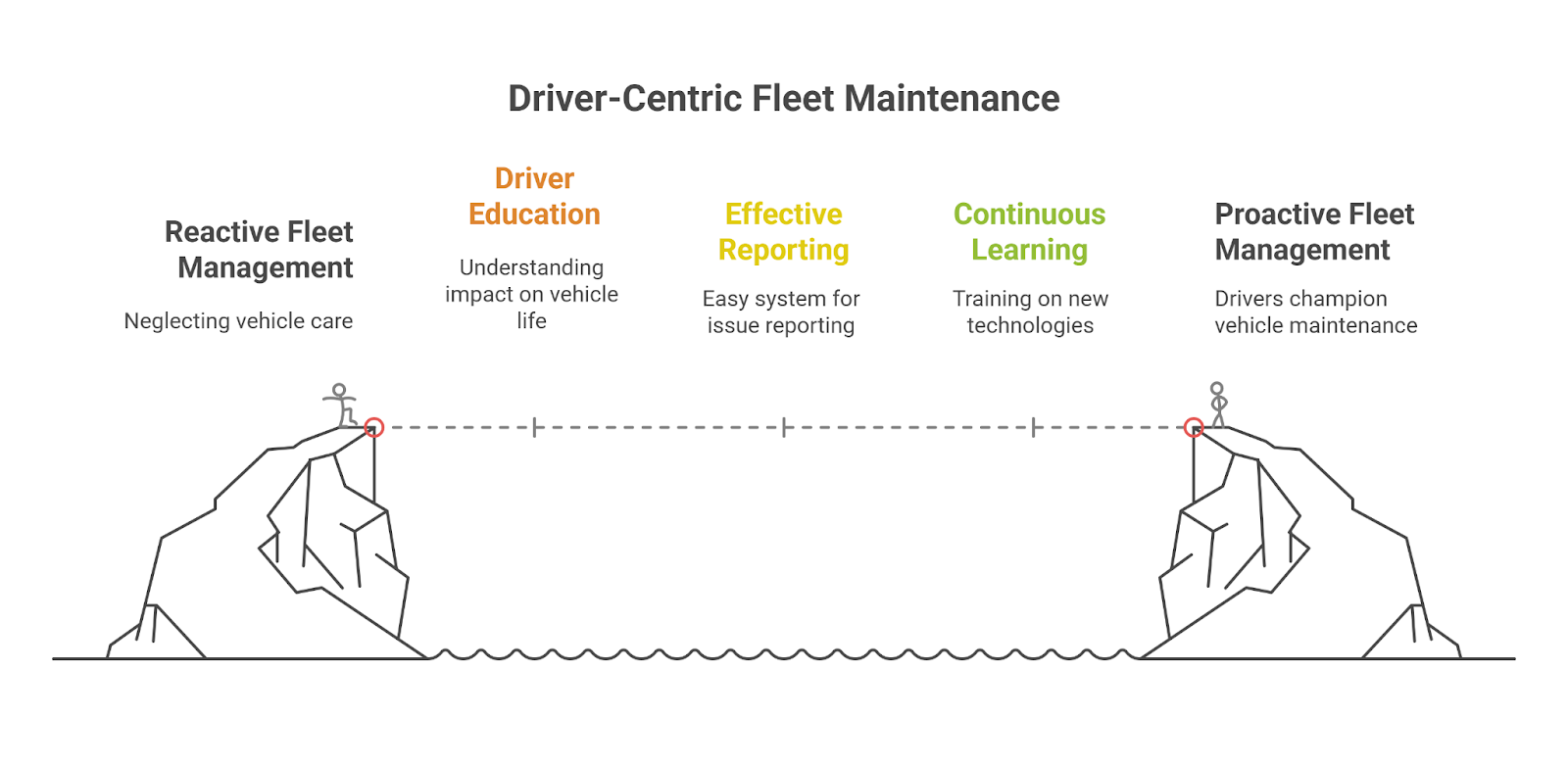

Building a Driver-Centric Maintenance Culture

Creating sustainable change in fleet operations is more than just training and procedure refreshers; successfully operating the most fleets systematically creates a culture that leads every driver to take ownership and to become invested in the maintenance and performance of every vehicle. This cultural shift begins with education but inherently infuses daily actions, methods of communication and everyday professional development.

Creating Ownership through Education

Creating ownership through education shifts the drivers from users of a fleet to advocates for their fleets. When drivers see how their actions impact the life of a vehicle and the profit of the fleet, their propensity to care for the vehicle and report maintenance increases.

Effective Reporting Systems

Effective reporting systems connect driver perceptions with maintenance actions. The reporting system should be an easy-to-use way, either digital or paper-based, to facilitate action for both major and minor issues observed by drivers.

What to include in a reporting system:

- Standardised language for common issues

- Ability to insert photographs

- Severity classifications

- Methods for tracking follow-up

Continuous Learning Programs

The continuous learning program will keep driver education current with the innovative vehicle technologies and fleet management solutions. Opportunities for training updates keep drivers aware of new technologies and reinforce best practices for vehicle care.

Modern Training Delivery Methods

The modern workforce is multifaceted in its scope; it also requires flexible, inclusive training that is aware of the different, and sometimes divided, ways people learn and work. The traditional classroom-style training method is not practical for the needs of the fleet operations today, as different drivers work different shifts, routes, etc. Successful truck management companies employ a multitude of training methods to cover all angles of training their drivers while leaving the maximum amount of knowledge retained.

Digital Learning Platforms

Digital learning platforms can provide flexible and scalable training delivery that fits the differences in driver schedules, as well as learning preferences or styles. These platforms can deliver interactive content, manage and report attendance/completion, and provide immediate feedback on a learner’s or driver’s performance.

On-Site Coaching Programs

On-site coaching programs provide an opportunity for hands-on or experiential delivery to complement learning that drivers can receive from digital mediums. On-site or one-on-one coaching approaches provide an instructor with an opportunity to model proper inspection techniques, as well as provide personal feedback on a driver’s or learner’s performance.

Ride-Along Assessments

Ride-along assessments provide a real-world experience for trainers to observe depot drivers in real time and provide live coaching to reinforce learning. This will also accurately vet where each individual driver needs to improve, additional support or training.

Measuring Training Program Success

Without proper measurement and evaluation, even the best-designed training programs fail to deliver their full potential. Fleet managers need concrete data to justify training investments and identify areas for improvement. Effective measurement systems track both immediate learning outcomes and long-term operational improvements to demonstrate the true value of driver education initiatives.

Key Performance Indicators

Key performance indicators for driver training programs should include both leading and lagging metrics. Leading indicators might include training completion rates and inspection report quality, while lagging indicators include breakdown frequency and last-mile fleet maintenance costs.

Important metrics to track:

- Reduction in unscheduled maintenance events

- Decreased truck roadside assistance calls

- Improved vehicle inspection scores

- Enhanced driver retention rates

Return on Investment Calculation

Return on investment calculation for driver training programs should consider both direct cost savings and indirect benefits. 48% of US fleet managers identify driver safety as a top priority, recognising that comprehensive training programs deliver measurable financial returns through reduced accidents, lower maintenance costs, and improved operational efficiency.

Transform Your Fleet’s Future Today

The most successful truck management company operations recognise that driver education isn’t just training—it’s a strategic investment in fleet reliability and profitability. When drivers become your first line of defence against downtime, every mile becomes more profitable and every delivery more reliable.

Ready to revolutionise your fleet’s performance? Contact Kooner Fleet Management Solutions today to discover how our comprehensive driver training programs can transform your operation from reactive to proactive, reducing downtime while maximising your bottom line.