In fleet management, speed doesn’t only matter on the road. It matters how quickly and effectively you can identify issues before they cost you. That’s where five-minute fleet checks come in. They’re short, consistent, and incredibly powerful for maintaining vehicle health, improving safety, and saving serious money on repairs.

Fleet managers often believe that proper inspections have to take up a lot of time or require advanced tools. The truth is, a well-planned five-minute routine can uncover early warning signs that prevent breakdowns, failed inspections, or expensive downtime. These checks aren’t a replacement for full maintenance, but they are a smart supplement that keeps your fleet ready and your expenses predictable.

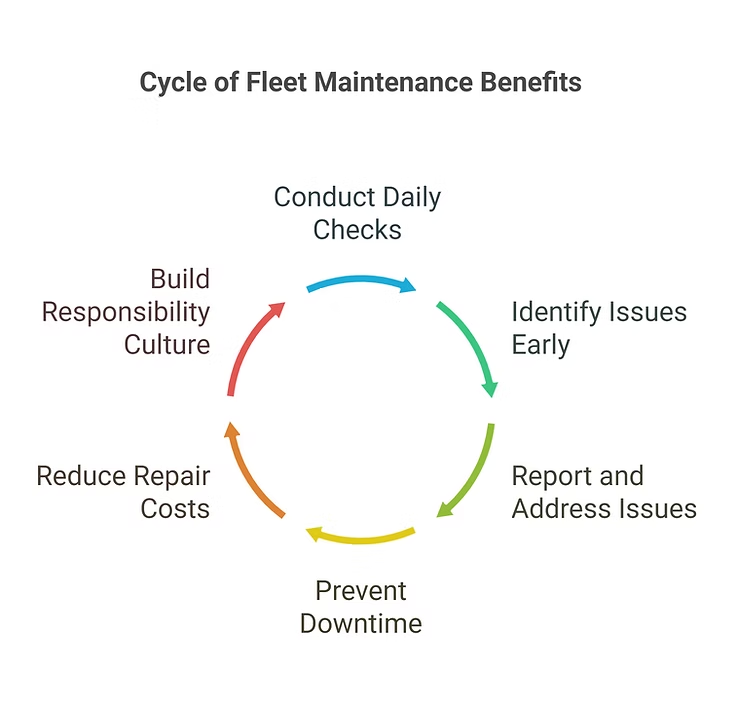

Why Are Daily 5-Minute Fleet Checks Important for Preventing Downtime and Costly Repairs?

When commercial vehicles are moving constantly, there’s little margin for unexpected stops. Every unscheduled breakdown isn’t just a mechanical issue. It’s lost revenue, missed deadlines, customer dissatisfaction, and potential penalties. A quick daily routine helps drivers catch issues early so they can be reported and addressed before they snowball into something worse.

Short checks also help build a culture of responsibility. When drivers feel like they have ownership of the vehicle they’re operating, safety and accountability improve across the board.

What Should Be Included in a 5-Minute Fleet Vehicle Inspection?

Here are the essential components of a fast but effective fleet vehicle inspection. Each one targets key wear points that tend to cause the most problems if ignored.

1. Tire Pressure and Condition for Fleet Safety

Uneven wear, low pressure, or damaged sidewalls are all signs of problems waiting to happen. Use a handheld gauge to check PSI, and do a quick visual sweep for any irregularities. Make sure treads aren’t worn down past legal limits.

2. Checking Fleet Vehicle Lights and Signals

Confirm that all lights and indicators are working. That includes headlights, brake lights, reverse lights, and turn signals. Visibility isn’t just a safety requirement—it’s also a DOT compliance issue that can lead to fines if overlooked.

3. Inspecting Fluid Levels and Signs of Leaks in Fleet Vehicles

Check under the vehicle for visible leaks, especially around the engine and undercarriage. Open the hood and inspect levels for oil, coolant, and windshield fluid. Catching a slow leak early can save you thousands in engine damage.

4. Mirror and Windshield Condition Checks for Fleet Visibility

Cracks, smudges, or loose mirrors reduce visibility. Drivers should take a quick moment to clean and adjust their mirrors and confirm the windshield is free of damage that could worsen with vibration or weather changes.

5. Brake Response Test During Daily Fleet Checks

While it may not be practical to remove wheels for a visual check, drivers can test brake responsiveness at low speeds in a lot or yard. Any squealing, pulling, or soft pedals should be flagged immediately.

6. Dashboard Warning Lights and Alerts in Fleet Vehicles

A glance at the dashboard can tell a driver a lot. Warning lights for the engine, brakes, or tire pressure should never be ignored. Even if the truck seems to drive fine, those lights often indicate early-stage mechanical issues.

7. Load Security and Trailer Attachment Inspection

For drivers pulling trailers, a walkaround should include making sure the trailer is properly latched, lights are connected, and the load hasn’t shifted. A loose strap or bent pin can cause major safety problems.

How Can These Quick Fleet Maintenance Checks Save You Money?

You might wonder how a few minutes could really lead to cost savings. But over time, the math speaks for itself.

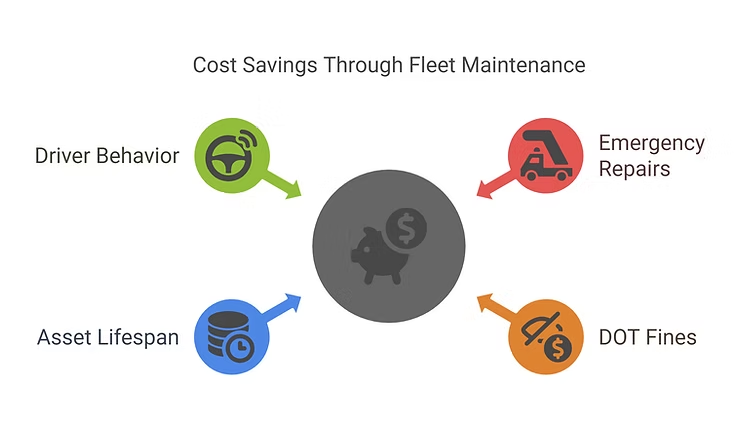

- Avoiding Emergency Repairs: Emergency roadside assistance can cost hundreds to thousands per call, not to mention delayed deliveries.

- Preventing DOT Fines: A failed inspection due to a broken taillight or low tire tread can lead to hefty penalties and damage your company’s compliance score.

- Extending Asset Lifespan: Consistent checkups reduce the wear and tear that comes from neglect. Components last longer, and the total cost of ownership drops.

- Improving Driver Behavior: When drivers check their vehicles daily, they become more familiar with how the vehicle performs and are more likely to report subtle changes before they become serious.

How to Train Your Fleet Drivers to Make Daily Checks a Habit

- Create a Standardized Fleet Inspection Checklist: Whether it’s digital or printed, a checklist reinforces habits and makes it easy to ensure nothing is missed.

- Set Expectations Clearly for Fleet Maintenance: Communicate that this isn’t optional. Five-minute checks are a part of the job and directly impact safety and performance.

- Reward Proactive Driver Behavior in Fleet Management: When a driver reports an issue that avoids a major repair, recognize it. Small incentives go a long way.

- Use Fleet Management Technology Effectively: Mobile apps can help log checks, report issues in real-time, and track patterns across the fleet.

What Does the Data Say About Cost Savings From Daily Fleet Checks?

According to a report by the American Trucking Associations, preventative maintenance can reduce fleet repair costs by up to 30%. Similarly, the Federal Motor Carrier Safety Administration found that brake violations were one of the top reasons for out-of-service orders in roadside inspections. Many of these issues stem from small problems that were visible long before they became violations.

Kooner Fleet Management Solutions has seen this firsthand. Fleets that implement daily checks often reduce roadside breakdowns by as much as 40% in the first three months alone. One client cut their emergency repair costs in half after just a quarter of consistent checks.

How Do 5-Minute Checks Build a Culture of Fleet Responsibility?

More than just a checklist, daily five-minute checks signal something bigger. They show drivers and managers alike that the health of the fleet matters, and that catching problems early is a shared responsibility. When teams care about the equipment they use, everything from safety to customer satisfaction improves.

At Kooner, we believe that the little things add up. A few minutes of care every day can save thousands in repair bills, boost uptime, and protect your reputation.

If you’re serious about keeping your fleet on the road and out of the shop, start with five minutes and contact Kooner Fleet Management for a superb all-around check. It’s not just a smart habit. It’s a smart investment.