When it comes to commercial fleets, everyone is talking about fuel efficiency, route optimization, and driver performance. However, there’s one detail that gets overlooked and has a huge effect on maintaining operations: battery health.

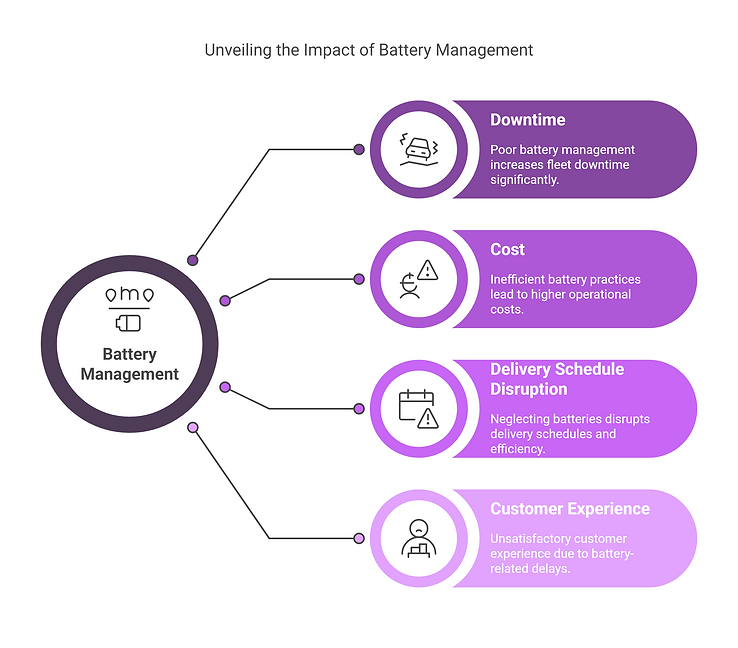

Bad battery management doesn’t just mean some occasional burdens; it means downtime, it means cost, and it causes a ripple effect that can disrupt the entire delivery schedule, making the customer experience unsatisfactory. According to the U.S. Department of Energy, poor battery management can lead to up to 20% more downtime for commercial fleets.

Best Practices For Truck Fleet Battery Management

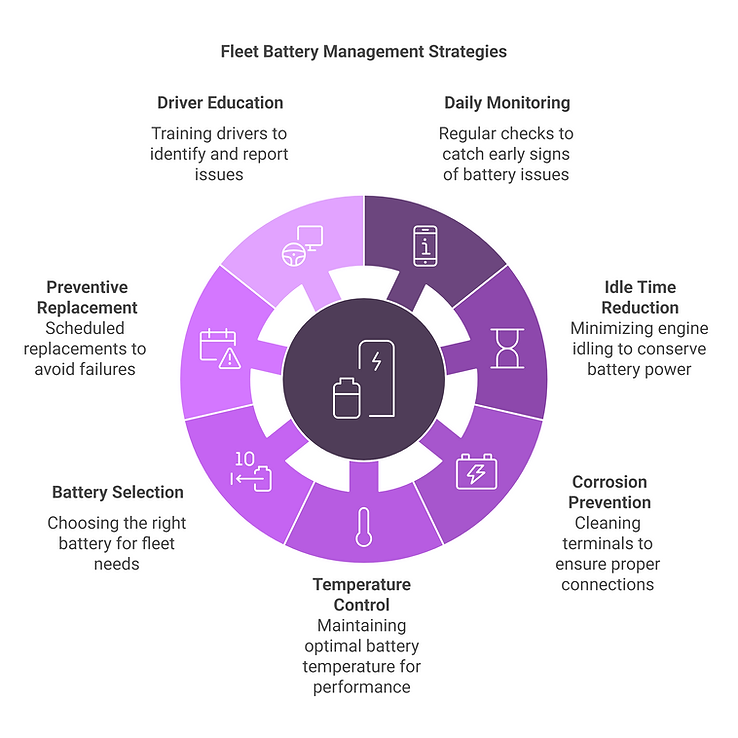

Here are some actionable and common-sense battery management best practices to keep you ahead of the game when it comes to modern truck fleets.

1. Make Battery Monitoring an everyday task

Batteries don’t just die without notice. It starts with the signals – low voltage, slow cranking, bad or inconsistent power output. The issue is catching one of the signals before you experience a problem while on the road.

Kooner’s fleet telematics solutions offer the ability to monitor the battery status on all vehicles in real time. This includes:

- Battery voltage trends

- Impact of idle time on battery discharge

- Warnings for inconsistent power usage

Daily checks help fleet managers solve battery problems before the battery causes an event that leads to delivery delays.

Pro tip: Set up automated alerts for drops in voltage and abnormal or inconsistent charging patterns.

2. Monitor Idling Time

Excessive idling wastes fuel, and it will consume batteries as well. If engines are running but vehicles are not moving, the batteries are working harder to provide power to lights, AC, and onboard electronics without the benefit of the alternator recharging them throughout the duration of idle time.

With real-time idle time tracking, your fleet can monitor which vehicles are idling excessively. From there, you can even set driver expectations or automated alerts to help limit engine-on time during vehicle stoppages.

This may seem like a small change, but it could lead to substantial savings in fuel cost as well as increasing battery life.

3. Check for Corrosion and Connections

The most innovative battery cannot function correctly if the terminals are corroded or not fitted properly to a vehicle. Perform periodic fleet maintenance checks under a regimented schedule that includes:

- Cleaning battery terminals

- Look for rust, leaks, or bulging

- Cables must be secured

Please train your drivers to identify failure points and report immediately. The checks take mere minutes, while batteries that fail can cost your fleet hours in downtime.

4. Be Mindful of Temperature

Batteries are sensitive to changes in temperature. Whether it is the frigid cold or dry heat, extreme temperatures can negatively affect battery performance and lifespan.

- Fleet managers should:

- Store spare batteries in temperature-controlled environments

- Consider purchasing battery warmers to keep them warm if your area sees extreme cold.

- Encourage battery testing before and after extreme conditions and seasons.

Even more, you should invest in the data insights to assess your fleet’s battery performance as it varies seasonally and geographically, and adjust preventative maintenance accordingly.

5. Choose the Right Battery for Your Fleet Type

All batteries aren’t built the same. What works for a passenger vehicle won’t hold up in a high-mileage delivery truck or a vehicle running power-hungry onboard systems.

When sourcing new batteries, look for:

- Manufacturer specifications based on vehicle type

- Higher reserve capacity for power-heavy use

- Deep cycle options for vehicles with frequent stops

Not sure what fits your fleet best? Kooner’s support team can help analyze your vehicle profiles and recommend battery options that support both performance and longevity.

6. Implement Preventive Replacement Schedules

Instead of waiting for batteries to fail, create a preventive replacement cycle based on usage hours, mileage, and battery health data. It’s a smarter investment in uptime and peace of mind.

For example:

- Replace high-usage batteries every 2–3 years

- Track usage patterns that suggest early fatigue

- Use data to flag at-risk batteries even if they’re within warranty

With our smart tracking tools, you can automate reminders and track battery life across your entire fleet without the manual headache.

7. Educate Your Drivers and Technicians

A well-trained driver is your first line of defense. Regular training sessions can help your team understand:

- Early signs of battery failure

- The impact of idle time and accessory use

- How to conduct quick visual inspections

Likewise, your technicians should be equipped with the right tools to perform diagnostic checks, battery load testing, and replacements quickly and safely.

The U.S. Energy Information Administration reports that battery storage capacity in the United States increased by 66% in 2024. Make it a team effort—battery health isn’t just a maintenance issue, it’s a full-fleet priority.

Smarter Battery Management Starts with Smarter Tools

Modern fleet operations demand a data-first mindset. And that includes how you manage something as critical—and often overlooked—as vehicle batteries.

At Kooner Fleet Management Solutions, our goal is to make fleet health more visible, predictable, and cost-effective. With real-time battery monitoring, automated alerts, and predictive maintenance support, you get more than just a data point—you get a clear path to more reliable operations.

Final Thoughts On Battery Maintenance Practices

Basically, battery issues creep up slowly and can really hurt your fleet’s efficiency if you ignore them. To avoid breakdowns, make your batteries last longer, and keep everything running smoothly, just take a few easy steps regularly. Smart tech can also help you make better choices about battery maintenance practices.

Kooner FMS makes battery health a seamless part of your fleet’s daily operations.

📩 Let’s talk. The road to smarter fleet performance starts with one charged decision.